Core Products

Intelligent Inspection Robot on vehicle’s bottom

Functions:

This intelligent inspection robot adopts automatic operation, which can realize the inspection vehicle automatically walking to the detection position and automatic detection. After the detection is completed, without manual intervention, it automatically returns to the position and charges to reduce the workload of personnel. The system replaces the traditional manual inspection operations with advanced dual-arm robot technology, vision technology, and image recognition technology to solve the problems in manual operation for EMUs' repairs and urban electric passenger trains.

The system consists of the following: fixed charging module, inspection railcar and track, on-board power supply and battery module, safety anti-collision detection module, high-precision positioning module, rapid scan detection module, key part detection module, and integrated smart handheld terminal. Market status

Market status

This product is domestic initiative, the technology is leading in market.

Application:

The product is mainly applicable to the maintenance workshop of EMUs, subway maintenance workshop.

This intelligent inspection robot adopts automatic operation, which can realize the inspection vehicle automatically walking to the detection position and automatic detection. After the detection is completed, without manual intervention, it automatically returns to the position and charges to reduce the workload of personnel. The system replaces the traditional manual inspection operations with advanced dual-arm robot technology, vision technology, and image recognition technology to solve the problems in manual operation for EMUs' repairs and urban electric passenger trains.

The system consists of the following: fixed charging module, inspection railcar and track, on-board power supply and battery module, safety anti-collision detection module, high-precision positioning module, rapid scan detection module, key part detection module, and integrated smart handheld terminal.

Market status

Market statusThis product is domestic initiative, the technology is leading in market.

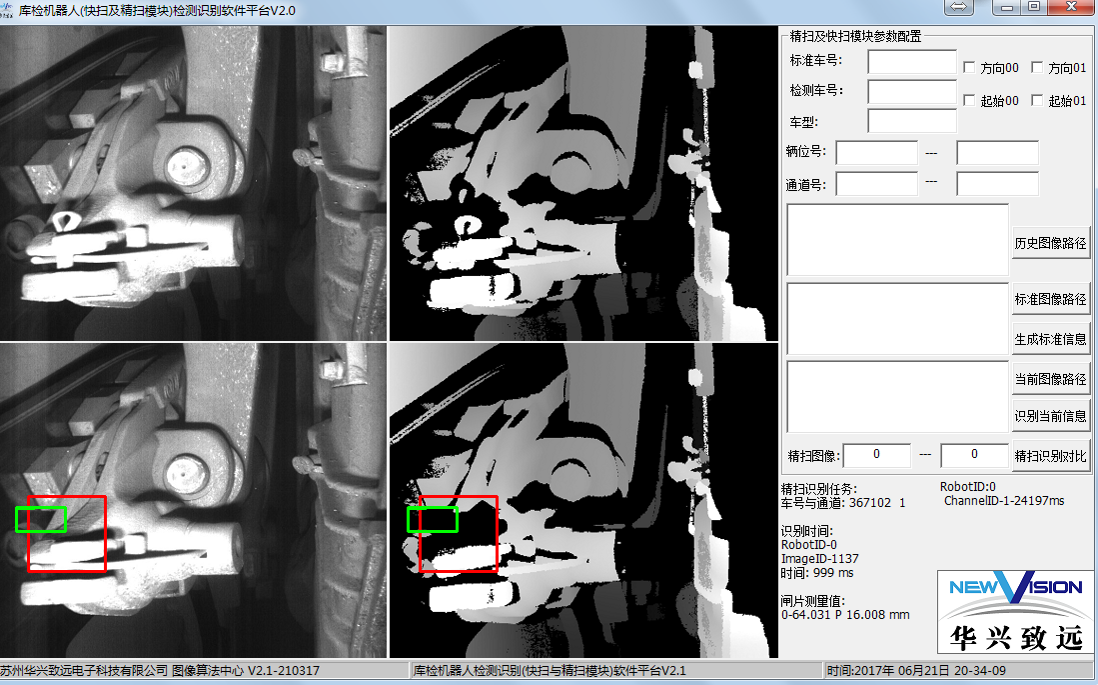

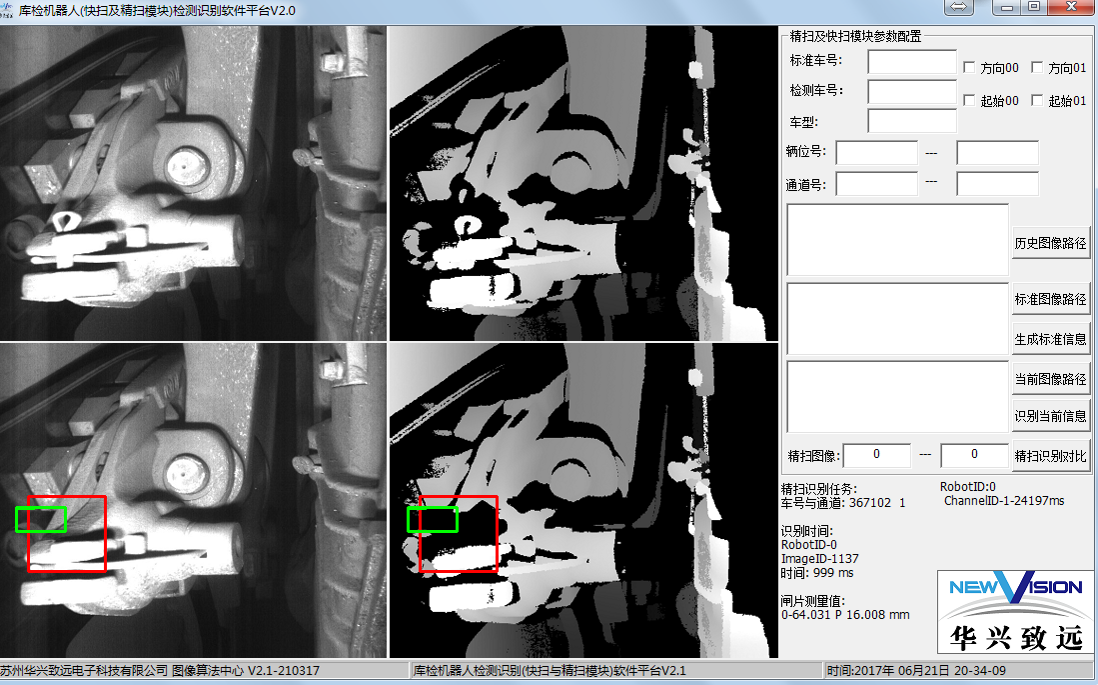

(Identify the split pin off)

Characteristics:- Automatic inspection

- Rapid detection on vehicle bottom

- Accurate positioning

- Security Anti-Collision Detection Module

- Multi-angle detection of key parts

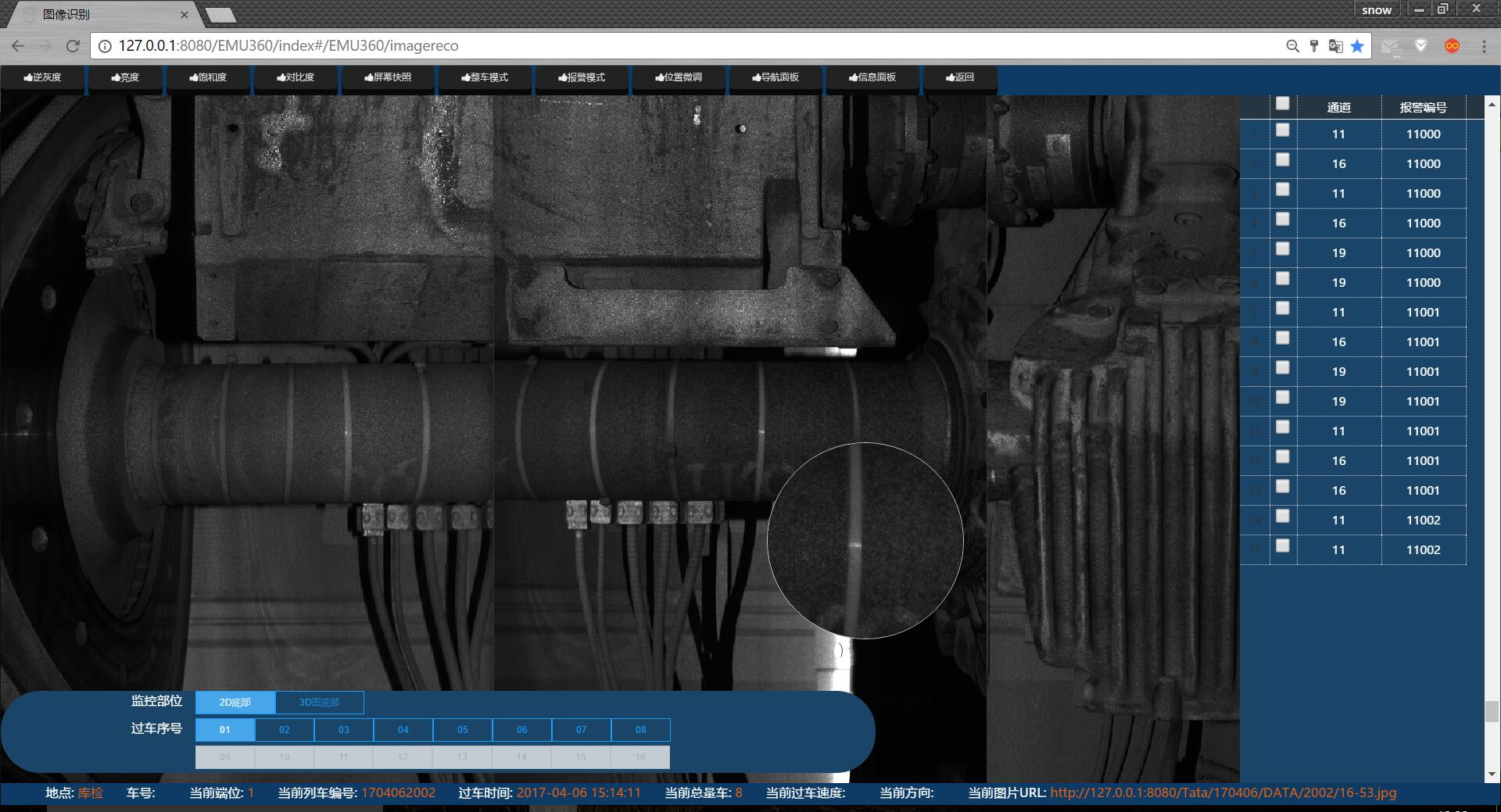

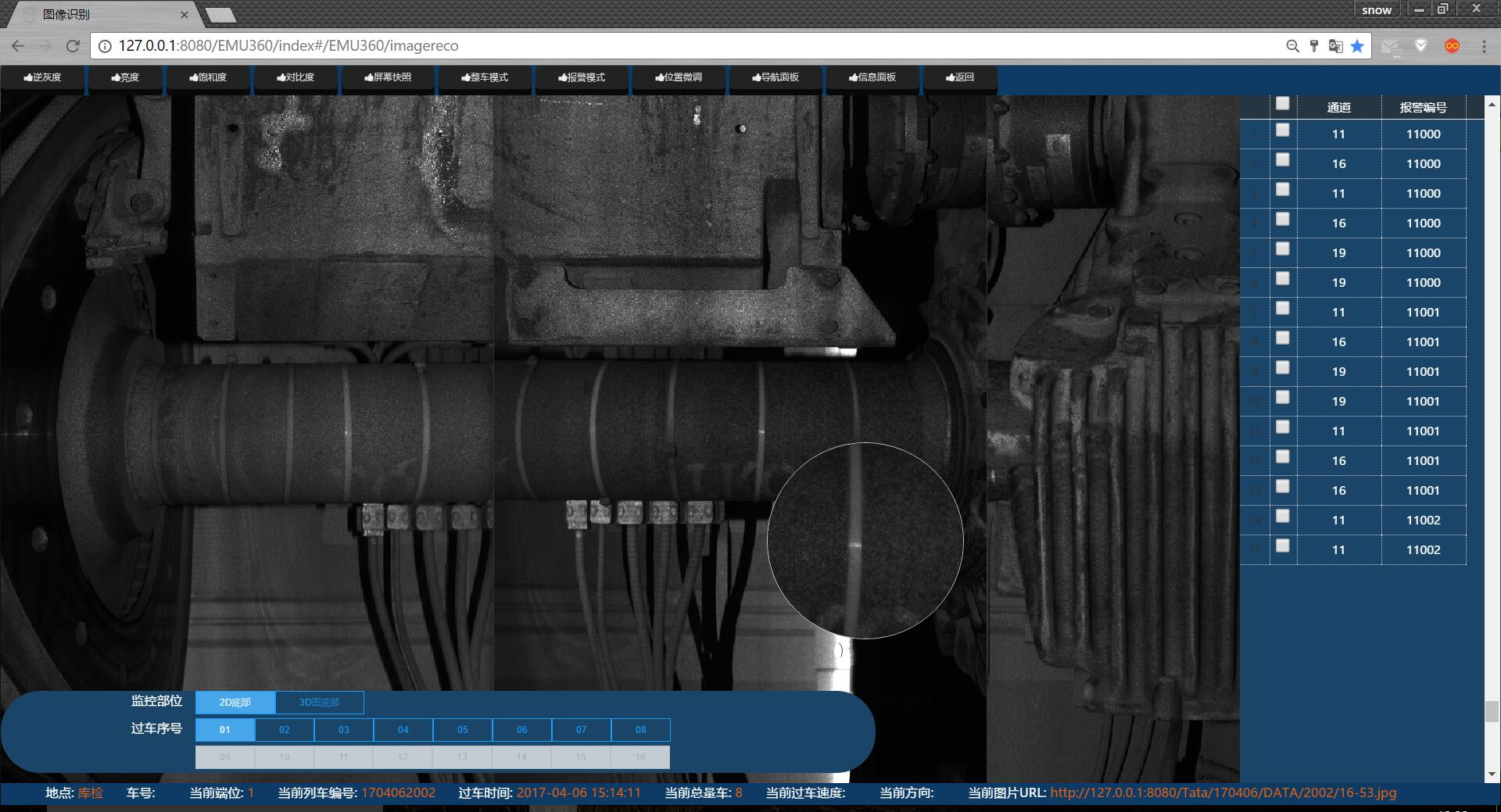

- 3D information collection

(3D information collection)

- Automatic fault identification

- Standard model generation

- Data interaction and comprehensive rating

- Anti-strong magnetic interference

Application:

The product is mainly applicable to the maintenance workshop of EMUs, subway maintenance workshop.

神州高铁技术股份有限公司

神州高铁技术股份有限公司