DIDMP is an integrated management of equipment information and detecting data of the integrated on-line detecting system platform that is suitable for all the rail locomotives, passenger trains, freight trains, high speed EMU and rail transit, etc. This platform covers real-time motoring of multi site, multi system and multi device working status, it also covers real-time alarm of the abnormal equipment status. Meanwhile, it is able to display the detecting result of all the detecting systems synchronously and helps to analyses the alarm remotely. It could count and manage the detecting data in classification. The equipment status and detecting results will be uploaded to data center in cloud storage way to ensure its security and reliable. The system platform could be able to make statistical analysis on history detecting data, business report output. You may do queries, statistics and data analysis via a certain way and display a friendly interface to users, adopts cloud computing to evacuate the data value deeply. It provides many functions like decision-making support data, maintenance warning, ledger management, operation monitoring and operation quality evaluation etc.

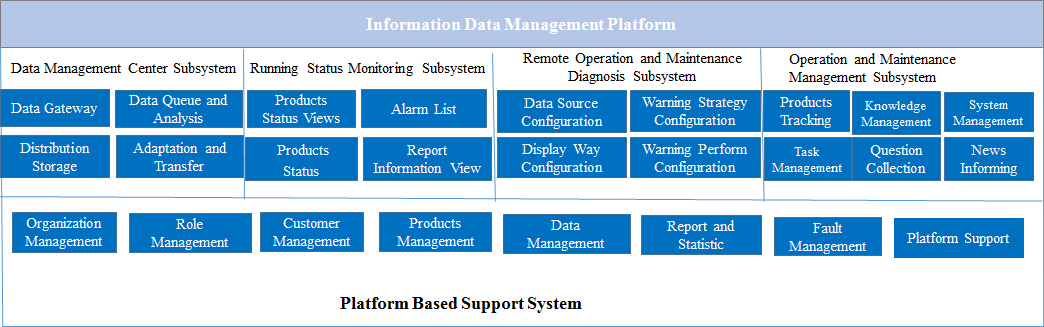

This platform, which is designed and developed by adopting B/S mode and MVC structure, is in strict accordance with the requirement of No.17, 2013 named EMU Wheel Fault Online Detecting System Technical Conditions and No.163, 2014 named Railway Passenger Train Wheel Fault Online Detecting System Temporary Technical Conditions both are issued by China Railway Corporation. Figure 1 shows the general system structure.

DIDMP has been running successfully since July, 2015. The online comprehensive detecting system in Jinan West depot, Harbin MU safety detection maintenance base and Xining Depot are accessing to this management platform, and there will be more sooner. With the running with this platform, the problem about difficult to manage the detecting data, difficult to monitor, difficult to check and difficult to do backup would be solved immediately.

1. Platform Constitution

Cloud data center platform system is based on Intelligent Extension Control Digital Platform. The upper layer is composed of data center management subsystem, product running status monitoring subsystem, products remote maintenance diagnose subsystem and operation & maintenance management based on mobile applications to form a frame called one platform, four subsystems. This completes the equipment running status daily monitoring in real time of multi sites, multi equipment, equipment inspection data analysis in real time, the management, etc. Meanwhile, it combines cloud computing technology and cloud storage technology to provide deep data value excavation, safe and efficient storage service of the multi sites & multi equipment inspection data.

2. Platform Features

(1)Provide accurate service to customer detecting data

Monitor the detecting data in real-time, monitor multi equipments from different depots in real time. Display the online detecting data of the rolling stock. Find the fault of the running gear in time. Coordinate the people who are in charge of the scheduling, quality testing, technical and safety maintenance to schedule the rolling stock, to analyses and handle the faulty information. It could assist customers to make a more professional analysis on data detecting result ensuring the operating efficiency and operating security of the rolling stock timely and effectively.

(2)Provide safe and reliable data storage to customers

In order to ensure the safe running of the rolling stock, the online detecting equipment will definitely produce a lot of detecting data, it brings you more extra work on integrity, security and management of the data storage with the historical detecting data accumulated gradually, in this circumstances, you have to increase the unnecessary equipments and personnel, the historical data would get lost when there comes the equipment fault and the incorrect operation. When simply disposing the data, you are unable to track the detecting history completely, unable to further analyses the deep value of the historical data, it is a data resource wasting.

Cloud data center brings a better service to customers by adopting cloud storage solution. It adopts a cloud storage database method that used by our company only to ensure the security of the data. Arrange hardware redundancy to protect the data losing due to the equipment faults. Fast parallel expansion, customers do not need to consider the storage space restriction. It is convenient to manage, simple to operate, you do not need extra data operation and managerial staff.

(3)Deep data value excavation

Undoubtedly, the detecting data of the equipments contains huge data value. However, due to the restrictions of the current products using, the data storage capacity and data calculation as well as the analysis ability, the value of the data is not released fully yet. It is a huge data wasting to customers.

Cloud data center uploads the relevant data to our company's cloud storage platform through secured and reliable data link to make a deep data value excavation by using high concurrent performance cloud computing. It is able to provide the previous status report of the rolling stock before they are maintained, wheel wear analysis and wheel reduction scheme, structure balance analysis and the trend development analysis of the wheel gear fault and other data service expanding projects after making deep data analysis and data excavation.

We have received a dozen of customers that required us for relevant data service when they are unable to obtain the deep value of the detecting data and detecting results.

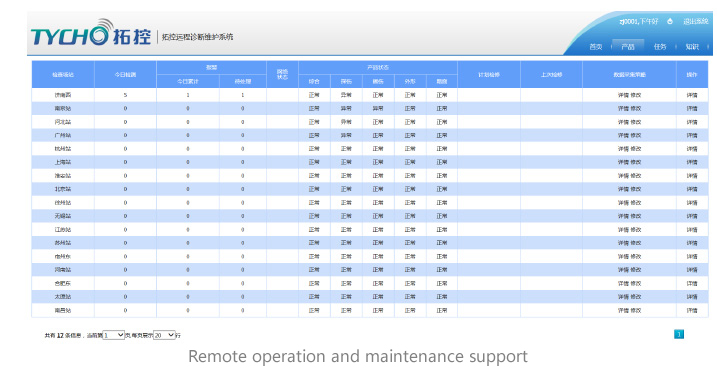

(4)Timely and effective remote equipment operation and maintenance support

We are able to monitor the equipment status information of multi sites and multi equipments in different depots and safety detection maintenance bases in real-time, provide timely and effective remote equipment operation and maintenance support, check the equipment running status in real-time, know the key parts running information in real-time, analyses the equipments running faults, assist customers to solve the equipment problems efficiently at the site, eliminate the possible hidden faults in advance. We are able to provide professional instructive suggestions, offer the equipment maintenance plan and supervise the entire progress, it is convenient to do management on equipments.

(5)Provide convenient mobile data terminal

Consider the problem of less staff, more equipments and heavy task, cloud data center launched a mobile application software APP for the convenience of the equipment managers to know the equipment running information whenever and wherever, to make a swift analysis, to contact rapidly and to find solutions quickly of the presenting problems.

神州高铁技术股份有限公司

神州高铁技术股份有限公司