Core Products

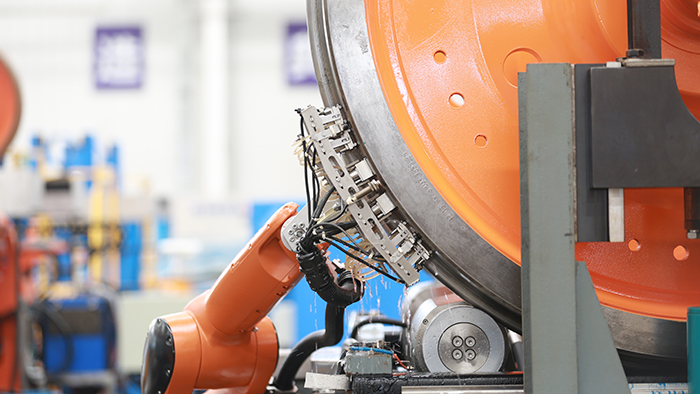

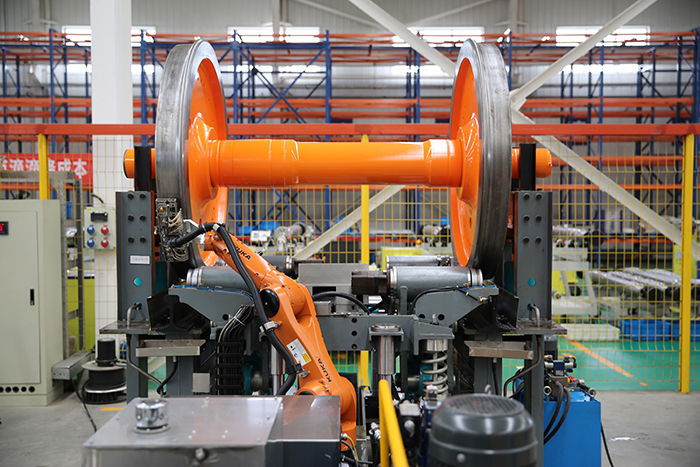

Locomotive online mobile rim spoke ultrasonic flaw detector

Locomotives on-line mobile wheel rim spoke ultrasonic flaw detection machine is applied to on-line inspection scanning of high-power locomotive wheels, which can detect rim defects on the rim, and spoke plate and internal defects.

- Test time≤ 15 min/wheelset

- Scanning time: ≤ 3 min/wheelset

- Probe angle: 0°~ 80°

- Wheel speed: Three-shift adjustable

- Maximum detectable axle load: 36t

- Adaptable wheel diameter range: 950~1250mm

- self-propelled speed range of the detection trolley: 0~300mm/s

- Probe positioning unit with collision protection: Maximum collision force<0.3kg

- Ambient temperature: 0℃~+55℃

- Altitude: 3000m

- Relative humidity: the monthly average is not more than 90%, and the maximum relative humidity is not more than 95%.

神州高铁技术股份有限公司

神州高铁技术股份有限公司